Please add image or text logo

The company owned 26 horses

By the end of the First World War the company had around 40 employees and supplied a wide range of timber, oak for railway wagons and fencing, ash for handles and cart shafts, elm for wheel hubs, with ironwork in-house.

Until the 1940s most haulage and extraction was done by horse – at one time the company owned 26 horses – 16 at Midgley and 10 at Wakefield.

Our first fencing centre

After the Second World War, the company started to evolve steadily. Premises in Wakefield were sold, a sawmill at Brigg in Lincolnshire was bought and large areas of woodland were acquired, which the company still works to this day.

With the decline of the region’s traditional industries of steel, coal and textiles, the company moved towards agricultural products, with fencing and gates taking over much of the mill’s production.

With the addition of a pressure treatment tank in the 1970s, much of the production shifted to softwood species. In the mid 1980s, the company launched its first ‘Fencing Centre’, a major initiative which took Earnshaws into retail operations for the first time.

Word soon spread

In many ways, the company was a pioneer, offering fencing and landscaping products, direct to the general public.

Though initial demand was steady, word soon spread, and the company was ideally placed to cater for the upsurge of interest fuelled by the makeover programmes of the 1990s. In 1996, following the closure of the local coal mine, the company relocated its entire Midgley based operation to the newly vacated 13-acre site.

The move allowed for the further modernisation of the sawmill operation, but in particular, enabled the further development of the retail and distribution enterprise.

Through the years

By about 1880 more power became necessary to develop the Sawmill, and the charismatic old traction engine was replaced with the purchase of an upright boiler and small steam engine of a few HP to drive more saws.

In 1914, the Directors met to consider the very serious question of investing in a motor car. They decided to buy a Ford car, a modest step which of course led to the eventual adoption of motor vehicles for all transport and carriage of timber.

A compound horizontal engine of 80 HP, built by Bradley & Craven of Wakefield was bought from Marshall, Kaye & Marshall of Ravensthorpe in 1916. A reservoir was made for condensation purposes and a Brick chimney built. The engine gave a good reserve of power. A suction plant for burning sawdust was installed, and an acetylene plant for lighting the sheds and houses. This was eventually replaced by gas. The chimney became a feature of the Midgley skyline until it was demolished in the mid ’60s following the change to electric power.

In 1923, Earnshaws installed the third phone on the Horbury Exchange – Horbury 3. The first two being the Police and the Town Hall!

Trouble with the hand crane in the Midgley yard led to consultations with the Yorkshire Electricity Power Co. to plan the electrification of the works and in 1939 this was gradually installed. The advantages of this power source radically improved productivity in many ways and quickly proved it’s worth.

Mechanisation and especially the use of early chainsaws, forklifts and Volvo loaders brought about radical changes to working practices and a dramatic reduction in the time taken to fell and process a tree.

Lorries with previously unimaginable payloads equipped with HIAB cranes streamlined loading and improved transport efficiencies even further.

Computerised control of processes in the sawmill made Earnshaws one of the most efficient in the country. Speed, economy and waste were optimised as concern for scarce and natural resources climbed up the social and political agenda.

Radical upgrade of the web site took Earnshaws fully into the digital and on-line age.

A brand-new web site was launched and a hugely improved broadband connection enabled significant improvements in IT and EPOS.

The sixties and onwards

From the early 1960s mechanisation started to enter the woods in the form of the early chainsaws such as the Jobu and the Dolmar – which dramatically reduced the felling time!

The next major leap was the introduction of Volvo BM loaders that could load logs onto the wagons without the need of wooden tripods and winch tractors.

By the 1970s, as the wagons got HIAB loading cranes the winch tractors were supplemented by tractors and forwarder trailers.

As the new millennium arrived, Earnshaws had become fully mechanised with nearly all softwood felling being undertaken by large mechanised processors that could fell in an hour, the volume a team of four men would have struggled to fell in a week, only a generation before.

Now, sadly, the only job left for the skilled timber feller is the largest hardwoods that the processors still can’t handle. Earnshaws still employ a gang of two men to do this job.

Where the fleet of old wagons struggled to carry a 12-tonne load, the latest HIAB equipped articulated fleet can carry payloads only dreamed of in the 60s. Loading now takes around 20 minutes whereas the old load would have taken two or three hours to get onto the wagon.

We know our timber

Many of the products we sell today are still made by hand in our own workshops, where quality and durability are second nature.

1998 saw the opening of a Fencing Centre on the sawmill site at Brigg. Replicating the success of the Centre at Midgley, the Brigg site brought the same wide range of fencing and landscaping products to customers from Scunthorpe to Lincoln and across to the East coast.

2007 saw the opening of the third Fencing Centre at the site of the old Wentworth Estate sawmill in the picturesque village of Wentworth near Rotherham. This site has since had a complete refit and has added additional joinery and panel capabilities to the company.

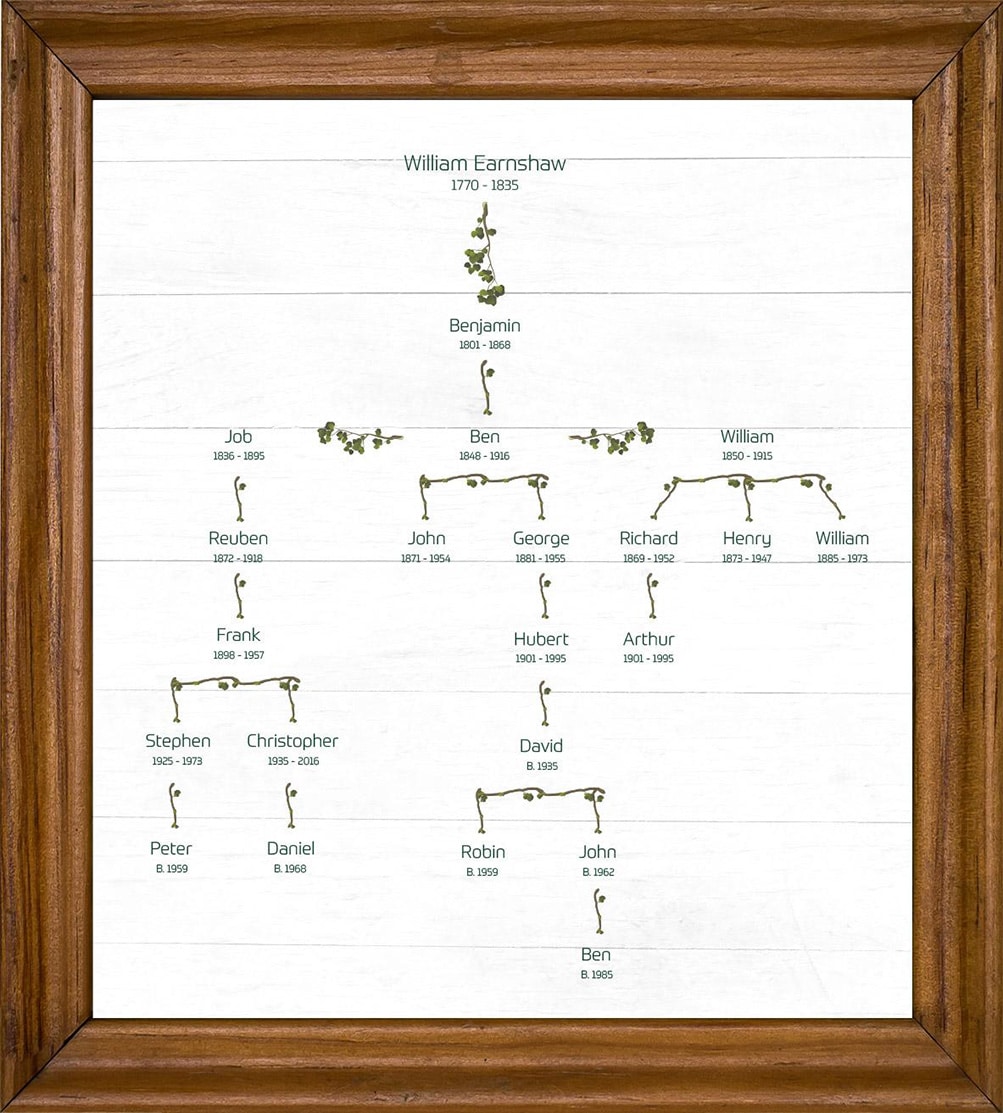

Earnshaws celebrates its 160th anniversary in 2020, the company is still owned and managed by descendants of the founders and we still maintain the same service tradition that was so important back in the 1860s. While the company has adapted and changed over the years we have built on those years of experience to be true experts in our field.

Proud of our evolution

We are equally proud of our evolution into an online and digital business. We have an active Facebook page engaging gardening and landscaping enthusiasts daily, and our loyalty card holders receive regular tips and updates by e-shot.

Our web site is frequently updated with company news and product information alongside gardening tips, environmental or wildlife stories, and downloads include guides and info graphics on key landscaping and garden design topics. Registered customers can also create, cost and track enquiries created from the comprehensive product listings.